Replacing your Marquee Lights with LEDs

Guest article written by Andy Thompson

The flourescent tubes for the marquee lights are extremely difficult to find replacements for if they have broken or gone out. Changing them out for LEDs instead of fluorescent tubes is a long term solution that is also more durable, not to mention both cost and energy efficient.

This guide will show you how to replace those tubes with LED strips.

Project Breakdown

Cost: $40

Time: 1 hour

Skill level: Low

What you Need

2x 19.7 inch LED tape light strips

AC to DC converter/power supply

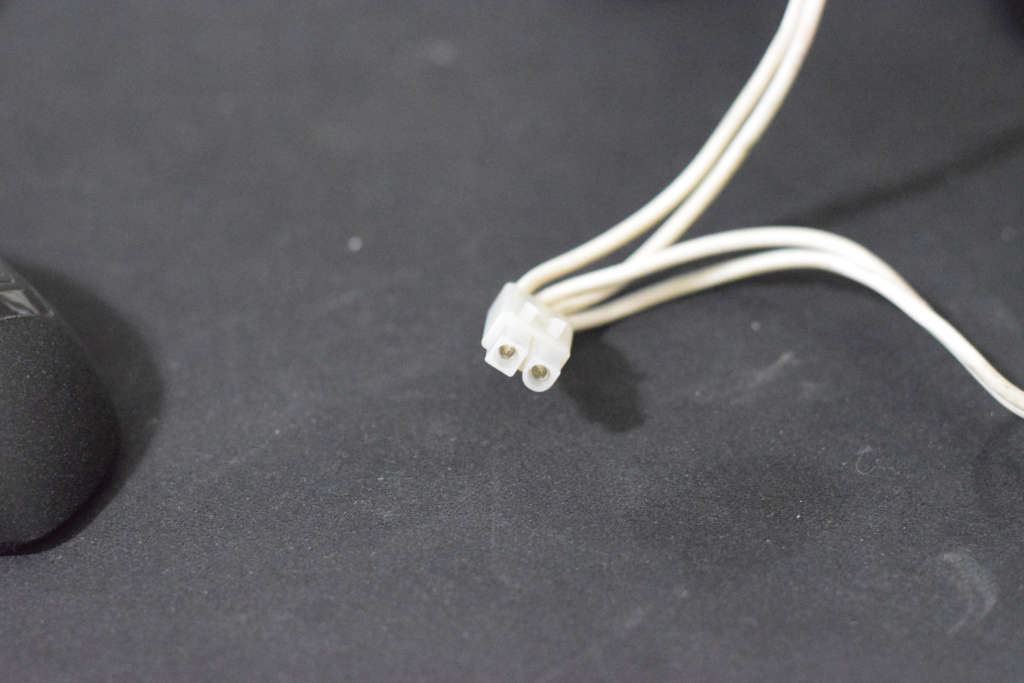

Male LC2 Connector cable

Screwdriver

Staplegun

4x Wire nuts

Wire Stripper

Step 1: Prepare the header.

To begin you may want to remove the header from the top of the machine. (Hint: see this guide for instructions on how to get the marquee down). It’s best if you have a friend help you do so. Disconnect the cabinet from power and make sure you unclip all the wires before taking the marquee down.

Take off the plexiglass and the marquee from the header. Remove the fluorescent light bulbs from the sockets.

Note: Fluorescent tubes contain mercury. THIS IS BAD. If you break one, don’t touch it! There’s also best practices for disposing of these tubes, they shouldn’t be thrown in the garbage or recycling. Refer to this guide for proper clean up and disposal.

Step 2: Remove the lights and clean the interior

There will likely be a plate covering the wiring and mounts to the lights. Remove this by pinching the plastic near the socket to slip the plate off. Remove the plate and unscrew the 4 screws and the lights will come free. Save two of the screws as we will be using them later.

When removing the lights the wires will likely be ziptied together with the speakers and the halogen lights so be careful when removing them. Cut the appropriate zip ties and everything will come out without much more fuss.

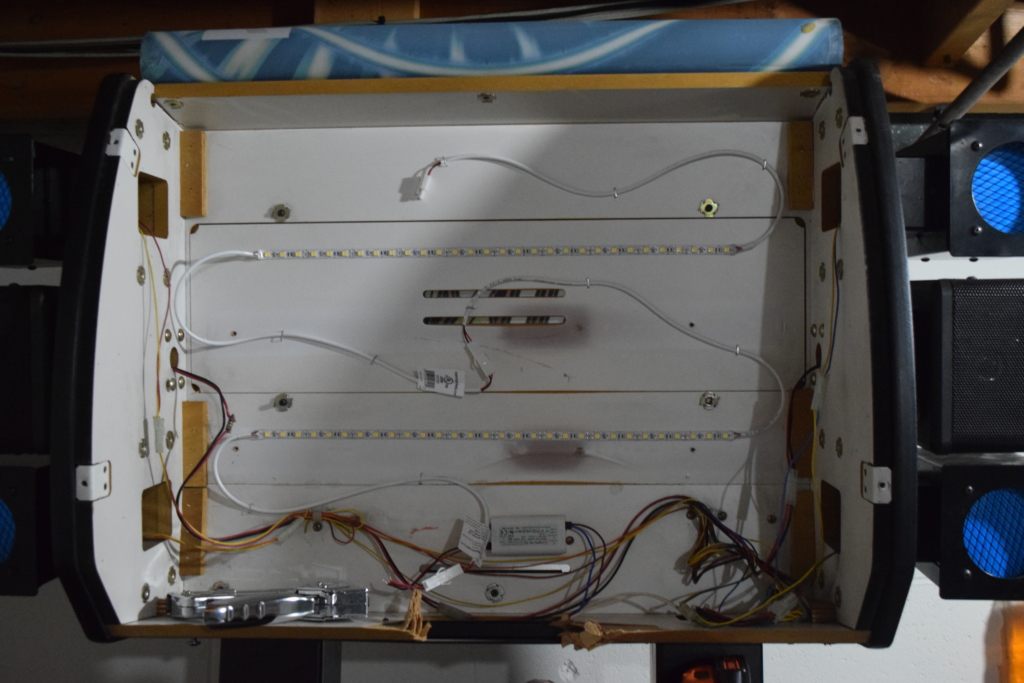

At this point you will want to clean out the interior of the header. You want to make sure the surface that you will place the lights is free of dust so they will be secure when placed on. Use rubbing alcohol to wipe down the surface; avoid household cleaners since they can leave residue which can interfere with the adhesive of the LED strips.

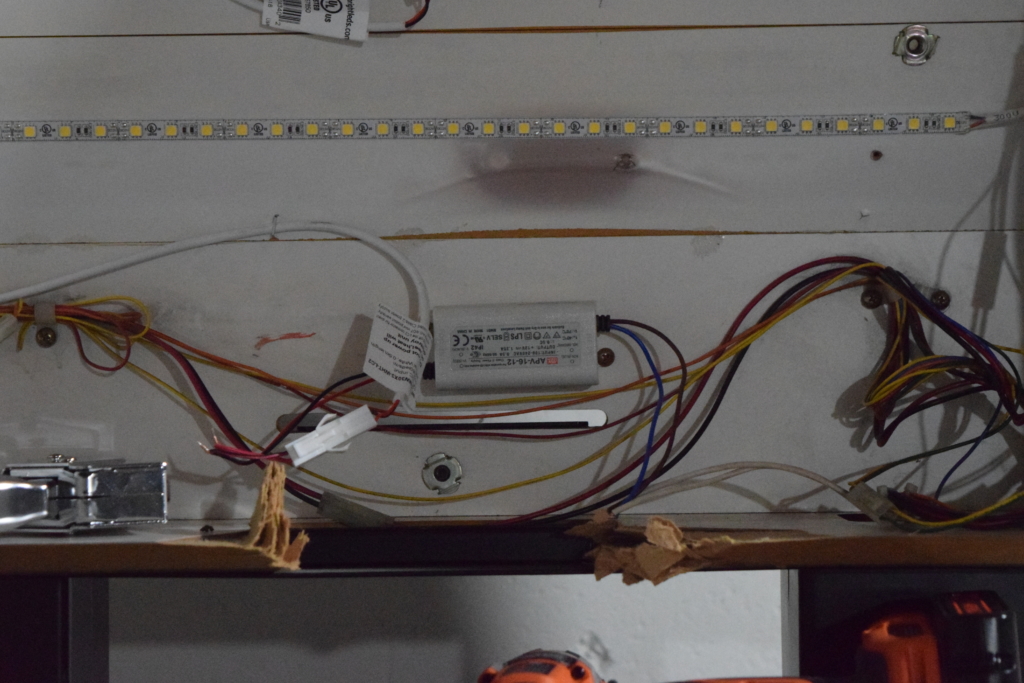

Ignore the damage to the bottom of my header as my header sustained significant damage during shipping

Step 3: Place the lights.

Since everything is clean at this point go ahead and peel the adhesive backing and stick the led into the header. I would suggest each LED strip should spread evenly in the header so it is diffused evenly.

Step 4: Wiring.

Since the input wires do not have any labeling on them we will want to determine the polarity of the wires. We should be able to use the connector to determine which is what polarity. If you have the polarity incorrect do not worry as it will not damage the power supply it will only not power on.

On the connector there will be two prongs. There is a square one and a rounded one. The wire which goes into square prong should be ACN (as labeled on the power supply) and the wire going into the rounded prong is ACL (again as labeled on the power supply.)

Use the wire cutters to cut the wire a few inches after the connector. There will be 4 wires (2 ACN and 2 ACL) you can cut down 1 of each polarity at the connector to prevent additional unneeded wires. Remove a bit of shielding and connect the ACN wire we found to the ACN(Blue) wire on the power supply and the ACL wire to the ACL(brown) wire on the power supply.

It is a good idea to test everything is wired up correctly at this point.

Reconnect the cabinet power and take the red and black wires from the power supply and touch them to the metal on the connector of the LEDs. (red to red, black to black). If it doesn’t turn on then the likelihood is the polarity from the input wires are backwards. Again, having the polarity backwards will not harm the power supply or LEDs, they will just not turn on.

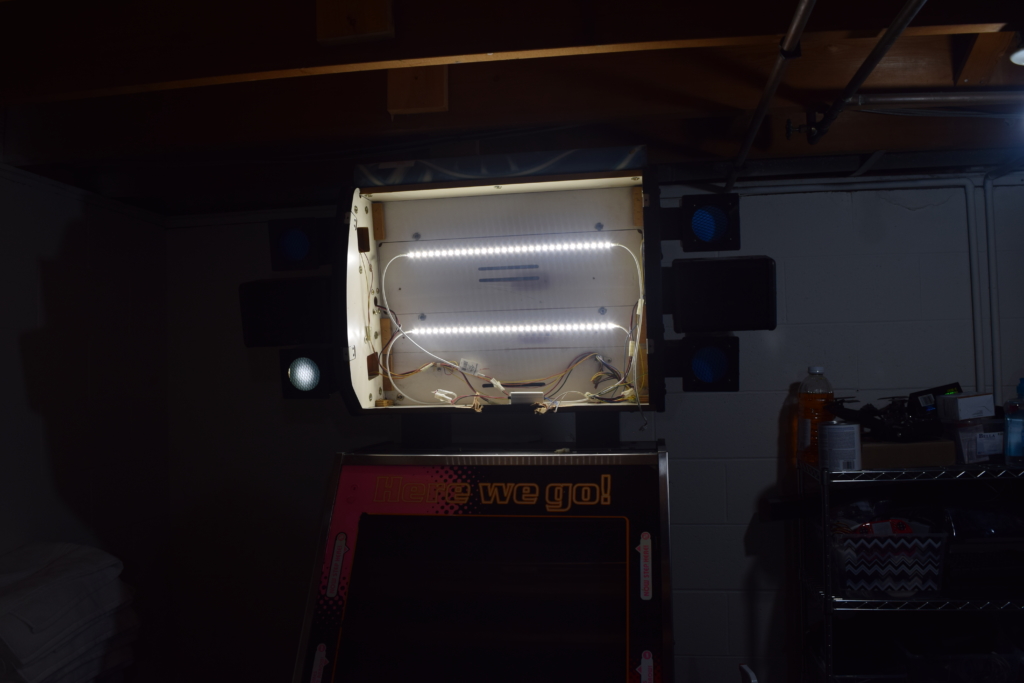

If your test was successful then take the spare connector and connect them with the black and red wires on the power supply. Place a wire cap on all the connections. Now we can plug in our new connector with the LEDs;If it doesn’t work at first, flip the connector around and try again to make sure the polarity matches. The LED strips can be chained together without any issue.

Step 5: Finishing up.

If you’re like me you hate cables dangling around. Take two of the screws which were used to mount the fluorescent lights to the header and use them to mount the power supply to the header.

I then used a staple gun to secure the cables to the back of the header and prevent them from dangling in front LEDs which may cause shadows or uneven lighting.

At this point everything is done we can put the header back on the machine. Plug everything in and power up the machine. Put the marquee and plexiglass back on and enjoy your fancy new LED marquee lights.

0